After experimenting with the stupid simple propane burner (see below) for a few weekends, today I threw together a Reil EZ burner with John Wasser's modification (unfortunately no longer available online) just like Todd's.

The Reil requires less hardware. It's smaller and lighter. It's simpler. And it worked the first time out of the gate. The only drawback is that you have to be able to drill a small hole. That's not really such a big deal. Coupled with the high pressure regulator, ball valve, hose, and other plumbing that I already had, this burner cost me $16 to build. With a little scrounging it could be nearly free.

There may be better burners than the Reil. For one thing I haven't welded with it yet, and I don't know how easy or hard that'll be. But for general forging, as long as you have some means of drilling a very small (#57ish) hole, it's very simple and very effective. I recommend it highly.

-Matt

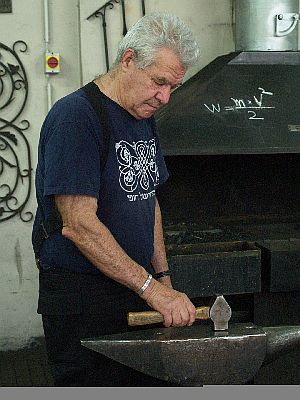

Something to think about...

...the dignity and importance of the smith's art is at once apparent. While others besides him use hammers, it is to the smith that they all must go for their hammers.

-Richardson

Saturday, March 8, 2008

Sunday, February 10, 2008

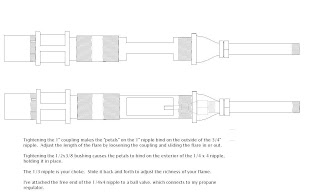

Stupid simple propane burner

This is a small, naturally aspirated propane burner that I just finished. It runs like a top on 10 p.s.i., and can probably handle more. It combines features from a number of other designs. The best thing about it is that it requires no drilling or tapping at all. In fact it could be made entirely without power tools. Of course electricty makes things easier.

UPDATE: After observing the burner for a while and doing some additional reading, I think the propane jet should be much deeper into the tube, more like so:

Thursday, January 24, 2008

Hammer Technique

This is a subject that is most important to me as a smith. I've heard and read a number of directions regarding the use of a hammer. I've also heard of smiths getting tendinitis from improper hammering technique. I was browsing through the iforgeiron site last night and came across a delightful tutorial on hammer use by the well-known smith Uri Hofi. Check out these links. I think you will be rewarded by what you read.

Wednesday, January 16, 2008

Arrowheads

I just made some medieval style socket arrowheads and took some photos of the process. You can find the album here. It also includes some great photos of arrowheads made by the professional British arrowsmith, Hector Cole.

Todd

Friday, December 28, 2007

The blade commission: What do we (or at least I, this time) get out of it.

By in large, the approach I’ve taken with regards to earning money making knives and other metal work, is that I hope to make enough to pay for the material and tooling costs I invest into my craftwork on the whole.

Some of the “standard” production items I make are priced to give me a reasonable hourly wage for the time it takes to make them, plus a little pay back on the capital investments. None of those, as yet sell at sufficient rates for me to seriously consider quitting my day job.

Commissions are a different beast. I don’t get nearly enough of them to be familiar or comfortable with the process. They are inevitably for a unique piece so I’m obliged to best guess the investment it will take to make it. Historically, they have all been from friends and relatives, or other people I have reason to admire and appreciate in the sort of way that makes me want to make them what they want, money aside. Thus further de-emphasizing concern for an accurate price quote.

A few months ago I accepted the most noteworthy to-date commission for a knife suitable for a Western Viking man, circa 850 c.e. with a recently completed, though later period Viking knife of mine as a base line for the level of complexity and ornament. My basis for quoting a cost were weak from the start, as I hadn’t kept all that good of track on how long it took me to complete the various elements of the base-line knife. Still I tried to assume that I’d make between $15 and $20 an hour.

I got to working on it, and it immediately became clear that in my time quote considerations, I was completely ignoring time spent researching, designing and negotiating for the most desirable design elements.

The design evolved as I went along too. The changes that which were driven by the customer, I felt at liberty to translate into price adjustments, but the great ideas I just had to try to satisfy myself, I thought best to absorb the cost of myself. That felt right, even if it wasn’t the most economically sound approach.

Now the knife is done. It is as full of flaws as any craftsperson is liable to note in their own work and yet I’ve been at this long enough to step back and observe that it really did turn out well. I also realize that the customer will likely be oblivious to most flaws and delighted overall, so it is with no shame that I turn it over considering the contract complete.

As for the $15 to $20 an hour: Boy, did I miss the mark there! Just tallying up time spent actually executing agreed upon design elements, I did not make $10 an hour; closer to $7 an hour. I kept better track of actual times there, so that, at least should improve for next time.

Adding the less well tracked research, etc. time, I estimate that I made something close to $4 an hour. Guess I had better keep my day job.

On the other hand, I have a real hard time being in any way distressed about this. I got a whole lot more out of this than just the money.

I was forced to expand my tooling capability to accommodate the larger than typical blade, and other special details. I learned how to do a few new things (and a few things not to do.) Design-wise, I learned how to construct original Oseberg style zoomorphs (an early Viking decorative style) which is something I’ve been meaning to do for years. That is all expanded capability.

I also have another way cool knife out there in public that folks are going to want to examine and perhaps covet their own enough to spawn more commissions. Granted, that would be the case, regardless.

And finally I made something special for someone (actually two people: The buyer and the person who will ultimately receive it as a gift) whom I already like and admire enough that I’d be interested and pleased to make something for them, even if money was not involved. That is perhaps the most rewarding of all, and something that would be far harder to come by if I were more effective at marketing, and economically sound quoting.

And I do still have my day job.

JoelS

By in large, the approach I’ve taken with regards to earning money making knives and other metal work, is that I hope to make enough to pay for the material and tooling costs I invest into my craftwork on the whole.

Some of the “standard” production items I make are priced to give me a reasonable hourly wage for the time it takes to make them, plus a little pay back on the capital investments. None of those, as yet sell at sufficient rates for me to seriously consider quitting my day job.

Commissions are a different beast. I don’t get nearly enough of them to be familiar or comfortable with the process. They are inevitably for a unique piece so I’m obliged to best guess the investment it will take to make it. Historically, they have all been from friends and relatives, or other people I have reason to admire and appreciate in the sort of way that makes me want to make them what they want, money aside. Thus further de-emphasizing concern for an accurate price quote.

A few months ago I accepted the most noteworthy to-date commission for a knife suitable for a Western Viking man, circa 850 c.e. with a recently completed, though later period Viking knife of mine as a base line for the level of complexity and ornament. My basis for quoting a cost were weak from the start, as I hadn’t kept all that good of track on how long it took me to complete the various elements of the base-line knife. Still I tried to assume that I’d make between $15 and $20 an hour.

I got to working on it, and it immediately became clear that in my time quote considerations, I was completely ignoring time spent researching, designing and negotiating for the most desirable design elements.

The design evolved as I went along too. The changes that which were driven by the customer, I felt at liberty to translate into price adjustments, but the great ideas I just had to try to satisfy myself, I thought best to absorb the cost of myself. That felt right, even if it wasn’t the most economically sound approach.

Now the knife is done. It is as full of flaws as any craftsperson is liable to note in their own work and yet I’ve been at this long enough to step back and observe that it really did turn out well. I also realize that the customer will likely be oblivious to most flaws and delighted overall, so it is with no shame that I turn it over considering the contract complete.

As for the $15 to $20 an hour: Boy, did I miss the mark there! Just tallying up time spent actually executing agreed upon design elements, I did not make $10 an hour; closer to $7 an hour. I kept better track of actual times there, so that, at least should improve for next time.

Adding the less well tracked research, etc. time, I estimate that I made something close to $4 an hour. Guess I had better keep my day job.

On the other hand, I have a real hard time being in any way distressed about this. I got a whole lot more out of this than just the money.

I was forced to expand my tooling capability to accommodate the larger than typical blade, and other special details. I learned how to do a few new things (and a few things not to do.) Design-wise, I learned how to construct original Oseberg style zoomorphs (an early Viking decorative style) which is something I’ve been meaning to do for years. That is all expanded capability.

I also have another way cool knife out there in public that folks are going to want to examine and perhaps covet their own enough to spawn more commissions. Granted, that would be the case, regardless.

And finally I made something special for someone (actually two people: The buyer and the person who will ultimately receive it as a gift) whom I already like and admire enough that I’d be interested and pleased to make something for them, even if money was not involved. That is perhaps the most rewarding of all, and something that would be far harder to come by if I were more effective at marketing, and economically sound quoting.

And I do still have my day job.

JoelS

Friday, December 21, 2007

Bloomery iron

Wrought iron has kind of a legendary status as the authentic smithing material, and for any smith who feels some connection with his or her historic roots -- and how many of us don't? -- there's bound to be some attraction to working with the stuff. What could be more satisfying than taking what is essentially dirt and turning it into the raw material of your craft? What's more, the woodgrain-like structure of wrought, which is caused by silica inclusions, can be very visually appealing. I've also read, though I haven't personally confirmed it, that there are things you can do with wrought that simply aren't possible with modern steel.

The problem is where to get the stuff. While wrought iroon was the primary ferrous metal for millennia, it was very labor intenstive to make. It's much simpler to make mild steel by modern industrial methods, so wrought iron has gone the way of the dodo -- almost. Generally, if you want wrought you have two choices: harvest it from an antique source -- there's lots of it still lying around - or make your own.

I've done the former, and I have a stash of wrought that will probably last me some time at the pace I work. But I have to admit that the latter approach appeals to me, too, and I'm almost certain to try it sooner or later. And when I do I'll be relying heavily on the work of the guys at the Rockbridge Bloomery, who as far as I know are the only people in the world today who're smelting wrought iron for commercial sale, using the same basic techniques that have been in use for thousands of years. I could tell you how bloomery iron is made, but then I've never actually done it. They have, and they tell you all about it on their site. So if you want to learn how it's done -- and maybe even give it a whirl yourself -- go take a look!

Once you have some wrought, you can make your own blister steel or crucible steel. I've experimented just a little with blister steel, and crucible steel is in my future. But those are subjects for future posts.

The problem is where to get the stuff. While wrought iroon was the primary ferrous metal for millennia, it was very labor intenstive to make. It's much simpler to make mild steel by modern industrial methods, so wrought iron has gone the way of the dodo -- almost. Generally, if you want wrought you have two choices: harvest it from an antique source -- there's lots of it still lying around - or make your own.

I've done the former, and I have a stash of wrought that will probably last me some time at the pace I work. But I have to admit that the latter approach appeals to me, too, and I'm almost certain to try it sooner or later. And when I do I'll be relying heavily on the work of the guys at the Rockbridge Bloomery, who as far as I know are the only people in the world today who're smelting wrought iron for commercial sale, using the same basic techniques that have been in use for thousands of years. I could tell you how bloomery iron is made, but then I've never actually done it. They have, and they tell you all about it on their site. So if you want to learn how it's done -- and maybe even give it a whirl yourself -- go take a look!

Once you have some wrought, you can make your own blister steel or crucible steel. I've experimented just a little with blister steel, and crucible steel is in my future. But those are subjects for future posts.

Wednesday, December 19, 2007

The Polished Edge

Here's a quote I found in Richardson's book by a smith of the 19th century. It helps understand clearly the value of polishing the edges of knives and cutting tools.

All cutting and piercing edge-tools operate on the principle of the wedge. A brad-awl furnishes an example which all can readily understand. The cutting edge of the awl severs the fibres of wood as the instrument enters, and the particles are compressed into a smaller compass, in the same manner as when a piece of wood is separated by a wedge. A chisel is a wedge in one sense; and an ax, drawing knife, or jack-knife is also a wedge. When a keen-edged razor is made to clip a hair or to remove a man’s beard, it operates on the principle of the wedge.

Every intelligent mechanic understands that when a wedge is dressed out smoothly, it may be driven in with much less force than if its surface were left jagged and rough. The same idea holds good with respect to edge-tools. If the cutting edge be ground and whet to as fine an edge as may be practicable with a fine-gritted whet-stone, and if the surface back of the cutting edge be ground smooth and true, and polished neatly, so that one can discern the color of his eyes by means of the polished surface, the tool will enter whatever is to be cut by the application of much less force than if the surfaces were left as rough as they usually are when the tool leaves the grindstone. All edge-tools, such as axes, chisels and planes, that are operated with a crushing instead of a drawing stroke, should be polished neatly clear to the cutting edge, to facilitate their entrance into the substance to be cut.

Every intelligent mechanic understands that when a wedge is dressed out smoothly, it may be driven in with much less force than if its surface were left jagged and rough. The same idea holds good with respect to edge-tools. If the cutting edge be ground and whet to as fine an edge as may be practicable with a fine-gritted whet-stone, and if the surface back of the cutting edge be ground smooth and true, and polished neatly, so that one can discern the color of his eyes by means of the polished surface, the tool will enter whatever is to be cut by the application of much less force than if the surfaces were left as rough as they usually are when the tool leaves the grindstone. All edge-tools, such as axes, chisels and planes, that are operated with a crushing instead of a drawing stroke, should be polished neatly clear to the cutting edge, to facilitate their entrance into the substance to be cut.

Subscribe to:

Comments (Atom)